Single Station Jounce Tester

Single Station Jounce Tester

The Single Station Jounce Tester is intended to evaluate either seat components or a complete seating system. The evaluation criteria are usually visual, but sometimes can be electrical (connections to seat heaters and other components), and sometimes audio. These include wear patterns, or general durability of the seat covering material, the foam, and the support structure underneath.

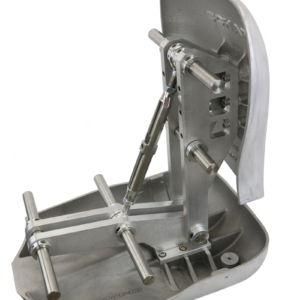

The upper jounce loading mechanism includes an appropriate body form and loose weights that can be added as necessary. This upper assembly is guided through eight ball bearings and four lightweight aluminum parallel arms, back to the main support frame.

The entire set-up is height adjustable to maintain horizontal parallelism of the arms using an attached bubble level. The entire set-up is laterally adjustable too so that it can be centered on the test sample. An overhead crane is included to suspend the loading mechanism while test samples are installed or removed.

It is important to notice that this type of mechanical design loads the test sample with the correct amount of body weight without inducing excessive inertia loads like some other test machines do. These high inertia loads on some competitive equipment increase the severity of the test and may cause some borderline samples to fail when they really should not.

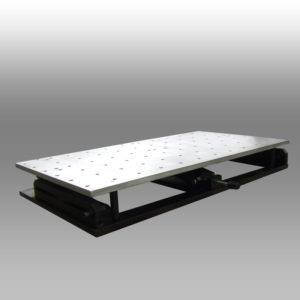

The lower jounce table is servo-hydraulic driven and operated with a P.C. based closed loop control system. The vertical movement is sinusoidal and programmable for both frequency and acceleration. Four control modes are available: Table displacement, table acceleration, upper assembly displacement or upper assembly acceleration.

For any given acceleration, the amplitude decreases as frequency increases. The system is also capable of frequency “sweeps” and other test-dictated sequences. The software is custom written by Schap Specialty Machine, Inc. in Visual Basic, which operates in a Windows operating environment.

Generally, this durability test system is rather simple to set-up and operate. Technicians that are P.C. literate will have no trouble quickly learning how to operate the machine and the software. With up to 178mm of vertical stroke, road simulation is also possible based on accelerometer data taken from a vehicle in use.

This tester can also be configured for your specific application upon request, please call or email your requirements at any time.

The Single Station Jounce Tester comes with one station, but additional slave stations (no data feedback) can be added (see Jounce Tester Stations). This allows you to test multiple samples of the same seat at the same time.