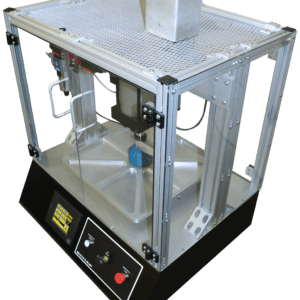

Mattress Rollator

Mattress Rollator

The Mattress Rollator is designed to comply with ASTM F1566 section 6 (Firmness Rating) and 7 (Durability Test). The test is performed by cycling a 240 pound hexagonal juggernaut across the width of a mattress for 100,000 cycles (200,000 passes); the equivalent of approximately 10 years of use.

It can accommodate a wide range of mattress sizes ranging from a Twin to California King. The PLC based control system is easy to operate. Simply enter the number of test cycles and the machine will automatically stop upon completion. In the event of a power failure, the hexagonal juggernaut is automatically retracted from the surface of the test and completed test cycles are stored to facilitate test restart once power has been restored.

Rollator Features:

- Durable, six-sided, 240 lb. hardwood roller assembly mounted on precision roller bearings.

- Roller assembly is laterally balanced.

- Roller assembly lateral position is mechanically adjustable.

- Roller assembly freely floats vertically, without air cylinder hysteresis drag, to follow the natural mattress construction.

- Roller assembly freely floats laterally (free to tilt if necessary, due to the natural mattress construction – like a real human).

- Roller assembly (240 lb.) is easily removable, if repair is ever needed, by removing a simple 2-bolt cap on the bottom of each end. The powered overhead lift has enough vertical stroke to set it directly onto a skid for removal.

- Roller assembly includes a metallic whisker for bleed off of excess static electricity build-up.

- Adjustable 2-axis / 4 corner table for mattresses from child to king size;

- Adjustment is manual and easy to perform.

- All lever tightening actions. No tools required.

- Corner adjustment cross bars include under-table mounted cross shafts and dual rack & pinion gears to prevent “dresser draw” binding while adjusting.

- No tie-down straps required.

- Overhead gantry with battery powered lift to automatically raise the roller assembly when the test stops – either at the end of the test or due to a power interruption. (Machine does not automatically restart after a power interruption.) Note that the lift will occur without building power, to save the accumulated test sequence.

- Automatic lowering of the roller assembly in case of excessive test sample degradation.

- Lower limit switch pauses operation in the event that excessive wear is achieved.

- Variable speed motor control to allow for easy adjustment of the cycle rate up to 20 CPM (depending on stroke), and to control overall test time.

- Programmatically adjustable roller assembly stroke, but always starting at one end.

- Sealed urethane wheels and stainless steel track for long life without lubrication (no grease on your pants). This also reduces operational noise.

- Center mounted timing belt main drive system.

- Trapezoidal motion so the roller accelerates and decelerates evenly.

- Separate, floor standing, control panel with a touch screen display, including:

- Mattress size selection.

- Operational speed.

- Cycle counter

- Start, stop & jog controls.

- Emergency stop is separate on the main console.

- Motor utilizes a mechanical brake upon activation of the E-Stop or a power interruption.

- Includes owner’s manual with operating instructions, schematic, replacement parts list, and manuals for all major components.

- No guards or light curtain supplied with this equipment, but can be added as an option.

- Footprint: 92” wide by 109” long by 80” high.

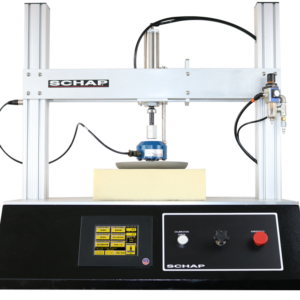

The Mattress Rollator can also be configured with IFD/ILD capability. Features include:

- Separate, carriage mounted vertical pneumatic actuator for fully automatic ILD / UTM test sequences using the main carriage vertical drive.

- Powered lateral slide adjustment and longitudinal lengthwise adjustment of the pneumatic actuator with programmable automatic positioning and compression test sequencing.

- Pancake style fatigue rated load cell, universal joint, 344mm (13.54″) disk. Note: Custom disks are available upon request.

- Programmable sequenced X-Y automatic positioning and compression testing is included.

| Weight | 2360 lbs |

|---|---|

| Dimensions | 2337 × 2769 × 2032 in |