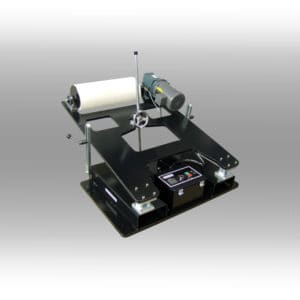

2 Station Sequential Fatigue Tester

2 Station Sequential Fatigue Tester

SCHAP’s 2 Station Sequential Fatigue Tester is a pneumatically driven cyclical load application machine that is P.C. driven with fully programmable load profiles. It can apply loads of up to 460 pounds (210 Kg) in either direction using 100 PSI shop air.

Standard Version

The standard version includes a 2 ½” bore x 10″ stroke tie rod type cylinder mounted with a center trunion, which provides single axis rotary motion from rearward of vertical (straight down) to above horizontal (facing forward). A counterbalance at the rear of the cylinder provides neutral forces when the rod is at mid-stroke, with a 500-pound capacity fatigue rated load cell and adapter plate installed.

Two adjustable hand clamps allow for either floating rotary motion (when attached to a test sample that is flexing under load), or rigid mounting (when pressing on and retracting from a test sample). This trunion mounting also provides approximately 6″ of side-to-side motion. If more than that amount of sideways motion is necessary, the entire vertical stand is bolted to the bedplate and can be moved.

The stand provides for approximately 30″ of vertical adjustment of the cylinder using a manual screw jack at the top and a pair of adjustable hand clamps to lock it in position. Beneath the lower limit of vertical travel, the legs of the stand are spaced for a wider stance so that a test sample can be placed directly under the cylinder with the rod pushing or pulling in a vertical orientation. The entire stand can be mounted anywhere on the bedplate or to a different bedplate, allowing for maximum test arrangement flexibility.

The included bedplate in this photograph is fabricated from steel (so that magnetic devices can be directly attached) with a 1″ thick ground top surface. It has an array of holes, through tapped for ½” –13 fasteners on 4″ centers, covering the entire surface.

With the Fatigue Test Stand removed, this bedplate can also be used for other purposes. The cylinder is controlled with a single servo-pneumatic directional valve that is mounted directly to the trunion assembly and connected to the main control console. The stand also includes a remote control console for local control, jogging and troubleshooting.

The load application of the cylinder is monitored in a closed-loop operating scenario from the load cell back to the servo controller to maintain the best accuracy.

The P.C. based control system is mounted in a floor standing console that is separate from the bedplate. The custom software is written in Visual Basic and is simple to operate for anyone familiar with Windows.

Almost any type of loading wave profile can be generated and then arranged into a test sequence. This test sequence then consists of differing wave profiles, each with their own cycle counts. This sequence can then be repeated as a loop counter. The combination of these two features gives this fatigue control system incredible versatility.

This standard tester operates on 115 V.A.C. and shop air. Set-up and operation requires minimal training and most technicians master it within an hour or so. It is also possible to incorporate multiple cylinders and stands into this mechanical arrangement and control system.

Other variations of our Sequential Fatigue Tester are available upon request. Please call 616-846-6530 for more information.