8 Station Pneumatic Fatigue Test Sequencer

8 Station Pneumatic Fatigue Test Sequencer

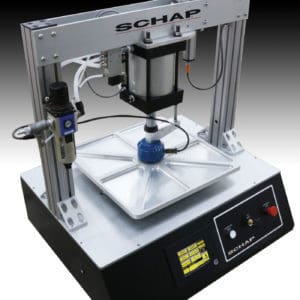

SCHAP’s 8 Station Fatigue Test Sequencer is a universal tester that uses air power (pneumatics) to test a wide range of products with forward-release-reverse-release control. It is easy to use, program, versatile, and very reliable.

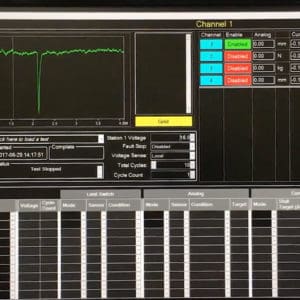

It is capable of operating up to 8 channels independently, simultaneously or sequentially, using up to 8 independent virtual test stations (a virtual test is any combination of up to 8 channels assigned to a single synchronized test sequence). Each channel is equipped with a separate pressure regulator for forward and reverse control. Test sequence setup is made easy by interactive graphics using simple click and drag software.

Sequences can be controlled by any combination of time or limit switches (or proximity sensors). A load cell converter box can be added to any channel so that force is a limit switch. Limit switches can also be used to determine over travel fault conditions.

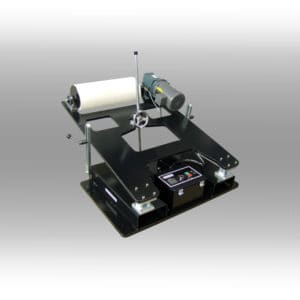

The entire control unit of the 8 Station Fatigue Test Sequencer is housed in a roll-around console and operates on standard 80 PSI of clean dry air and 120 V.A.C.

Some of the tests that it can do include:

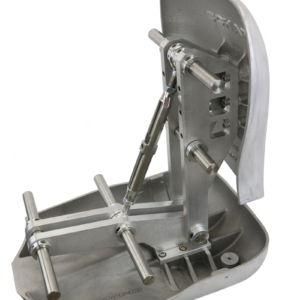

- Manual seat life cycle tests

- Loading and unloading of a seat with a form

- Applying a timed or force controlled load on a seat/seat back/seat arm to a distance (limit)

- Other mechanical tests where the air controls of the tester can be utilized with your cylinders, limit switches, or load cells.

Once the test sequence has been created, it can be saved for future use.

Utilities: Electrical power plus shop air (typically 80 psi), 120 VAC.