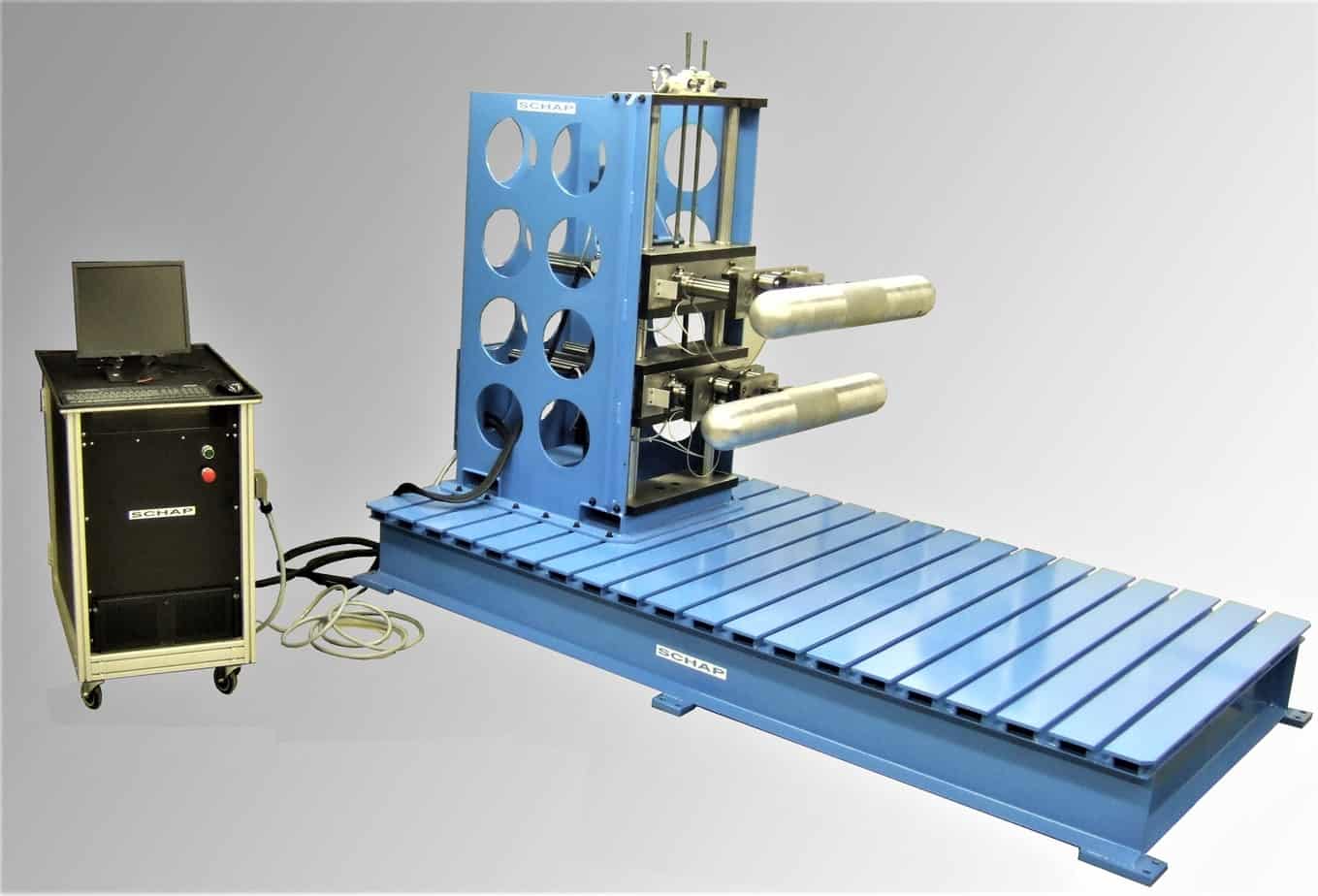

Bus Seat Tester

SCHAP’s Bus Seat Tester is designed and built specifically to satisfy the requirements of both NHSTA S5.1.3 and S5.1.4. It is intended to be attached to the customer’s existing bed plate, or it can be provided with one. All mechanical functions are completely electric – nothing hydraulic!

The basic Bus Seat Tester is built with 2 ½ inch (63.5mm) diameter solid steel shafting to provide all linear adjustments and motions while maintaining ample machine rigidity. The upper and lower beams are both manually adjustable for height with crank handles on the side. Extend and retract speeds are both variable speed and adjustable through the software program.

The P.C. based Control and Data Acquisition System is included and housed within a directly attached console. The software is custom programmed by us in Visual Basic, and operates in a standard Windows environment. Data acquisition of both load and position is automatically plotted for each ram with a wide selection of user and display options.

The final graphical result can then be printed on the plain paper color ink jet printer, which is also housed within the console. This test data can also be saved or downloaded onto any other suitable P.C. type format.

Generally, this destructive test system is rather simple to both set-up and operate. Technicians that are basically P.C. literate will find the software is user friendly and easy to operate.