The ORIGINAL Wyzenbeek Abrasion Tester

The ORIGINAL Wyzenbeek Abrasion Tester for Fabric & Leather

SCHAP’s ORIGINAL Wyzenbeek Abrasion Tester for Fabric & Leather is used to determine the abrasion resistance of textiles, fabric, vinyl, leather, stitched seams, and other materials. The Wyzenbeek test method is widely accepted in these industries.

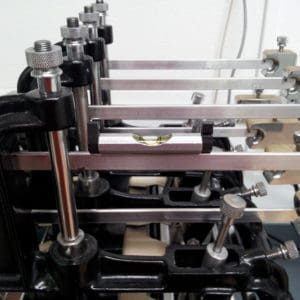

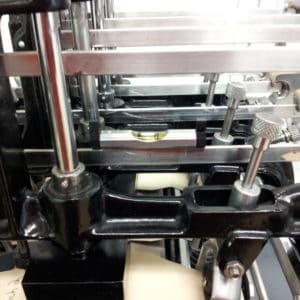

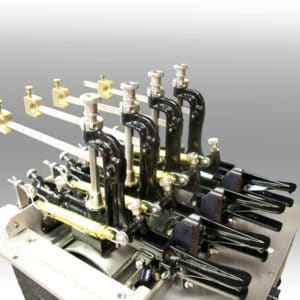

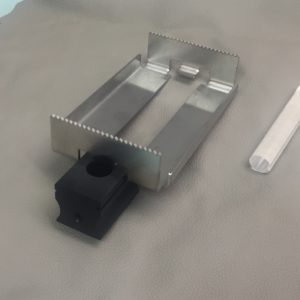

The Wyzenbeek Abrasion Tester for Textile & Leather is a four station oscillatory abrasion tester used to determine abrasion resistance of fabric, vinyl, leather, stitched seams, and other materials. Each station holds a specimen taut and utilizes contoured foam pads to apply pressure while an abradant (typically duck cloth or wire mesh screen), which is affixed to the oscillating drum, abrades the specimens for a prescribed number of cycles.

Each of the 4 stations have individual specimen tension and pad pressure settings.

If your machinery requires CE conformity, our Wyzenbeek CE Model Abrasion Tester meets these requirements.

Advantages of the Wyzenbeek Classic

The Wyzenbeek Classic Abrasion Tester is lower in price than the Wyzenbeek CE model. It does not include added safety features or CE compliance. With the Wyzenbeek Classic open design, it is easier for the operator to load, and make adjustments to the abradant on the drum (setting tension, position, etc.). Some operators prefer this open design.

Features of The ORIGINAL Wyzenbeek Classic Abrasion Tester:

- Robust mechanical components are constructed of Aluminum and Solid Stainless Steel

- Durable Powder Coat and Anodized finishes

- High Quality THK Precision Bearings

- Open air construction prevents overheating from friction

- Programmable count-up controller with automatic stop

- Adjustable jog and test speed controls

- Supply voltages vary and must be specified at time of purchase

- High quality brushless electric motor

- 1 year manufacturer’s warranty

The Wyzenbeek Test Method

Individual test specimens cut from the warp and weft are rubbed back and forth using an AATCC approved #10 cotton duck fabric, or wire mesh screen as the abradant (Both available from SCHAP).

Each station holds a specimen taught, utilizing contoured foam pads to apply pressure. The abradant is affixed to the oscillating drum, which abrades the specimens for a prescribed number of cycles.

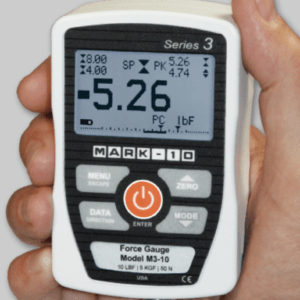

The end point is reached when two yarn breaks occur or when appreciable wear is reached or when 100,000 double rubs are reached. The samples should be checked every 5,000 double rubs, and when an end point is reached because of failure, the rater should back up to the previous 5,000 double rub checkpoint as the test result of abrasion resistance. The test results are therefore to be reported in 5,000 double rub increments.

Rental Options:

This Item is Available for rent OR Lease to own. Call 616-846-6530 for more Information.

(rental equipment is ONLY available in the continental US)

| Weight | N/A |

|---|---|

| Dimensions | N/A |